-

Booth No. :C21

11 - 13 September 2024

BALAI SIDANG JAKARTA CONVENTION CENTER, INDONESIAContacts:GUO LIANG

Email:jack@farfly.com

Tel:0086-18625250173

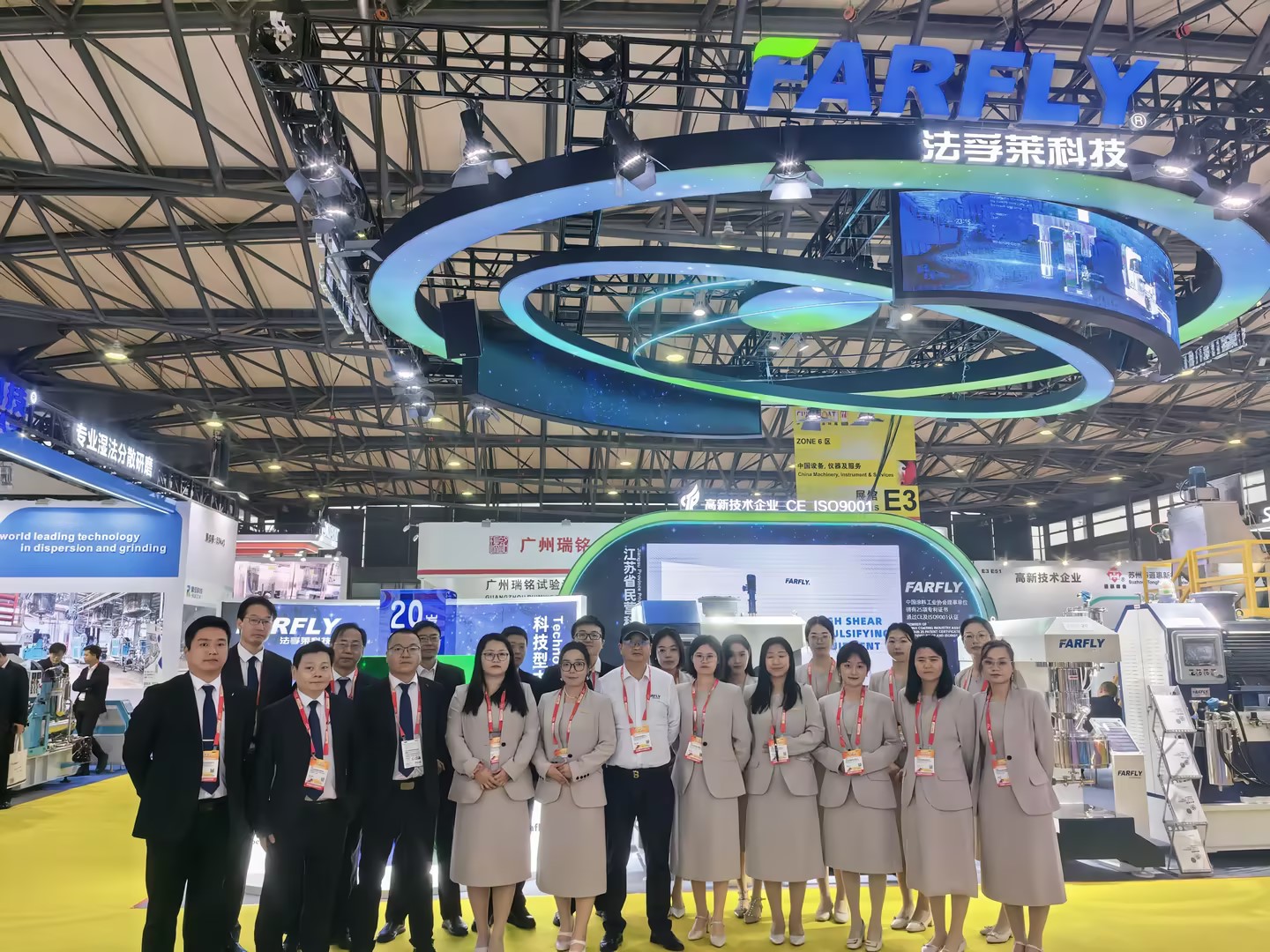

Welcome to Asia Pacific Coatings Show, APCS 2024

Aug 23, 2024

The Asia Pacific Coatings Show is the leading event in South East Asia and the Pacific Rim for the coatings industry. For three days, the exhibition offers the opportunity to meet new and existing customers from the region; gather insight on the latest technologies available in the market; and have meaningful, face-to-face business interactions.

The event provides the perfect environment for the entire spectrum of the coatings industry to do business, from raw material suppliers to equipment manufacturers, to distributors and technical specialists like formulators. That’s not all – the conference that is held alongside the event offers the opportunity to learn about the latest industry products, innovations and trends; exchange ideas with industry leaders; and build a strong network in the region.

Information for visitors

Characteristics

The stirring paddle in the kettle rotates during revolution,which makes the material flow around, so it can realize mixing

(compounding) effect in a short amount of time.

There are various blades such as frame, paddle and dough twistingframe for low speed blades that can be chosen.

Vacuum design ensures the material is working under sealedenvironment.

Heating means of kettle can be electrical heating, steam heating, hotwater or oil circulation heating; intelligent temperature director can control temperature precisely.

FXDJ Double planetary mixer

Characteristics

The stirring paddle in the kettle rotates during revolution, which makes thematerial flow around, so it can realize mixing (compounding) effect in a short amount of time.

The additional one or two high-speed disperser in the kettle rotate duringrevolution, which makes the material cut strongly and mixed, the effect is severalfold superior than an ordinary mixer.

There are various blades such as frame, paddle and dough twisting framefor low speed blades that can be chosen.

Vacuum design ensures the material is working under sealed environment.

Heating means of kettle can be electrical heating, steam heating, hotwater or oil circulation heating; intelligent temperature director can control temperature precisely.

Application area

Digital printing ink, solvent ink, water-based ink, automobile paint, industrial coating, pigments, color paste, and nanometer materials.

• New design of pin-type grinding components,high grinding efficiency high output, and low energy consumption.

• With smaller length/diameter ratio and higher energy density.

• Using high flux static centrifugal separation sieve, large discharging area, grinding medium no contact with the sieve, no

abrasion, with longer service life.

• Grinding Barrel and grinding rotor adopt forced cooling system, with lower discharging temperature and no influence on sensitive

materials.

• Using top high quality wear-resisting alloy steel, reduce pollution to products. Different materials are optional as per different

products, such as stainless steel, high polymer materials, ceramics, etc.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Sep 22, 2025

ABRAFATI SHOW 2025.jpg?x-oss-process=image/resize,w_100/quality,q_100)

May 27, 2025

Welcome to West Africa Coatings Show, WACS 2025