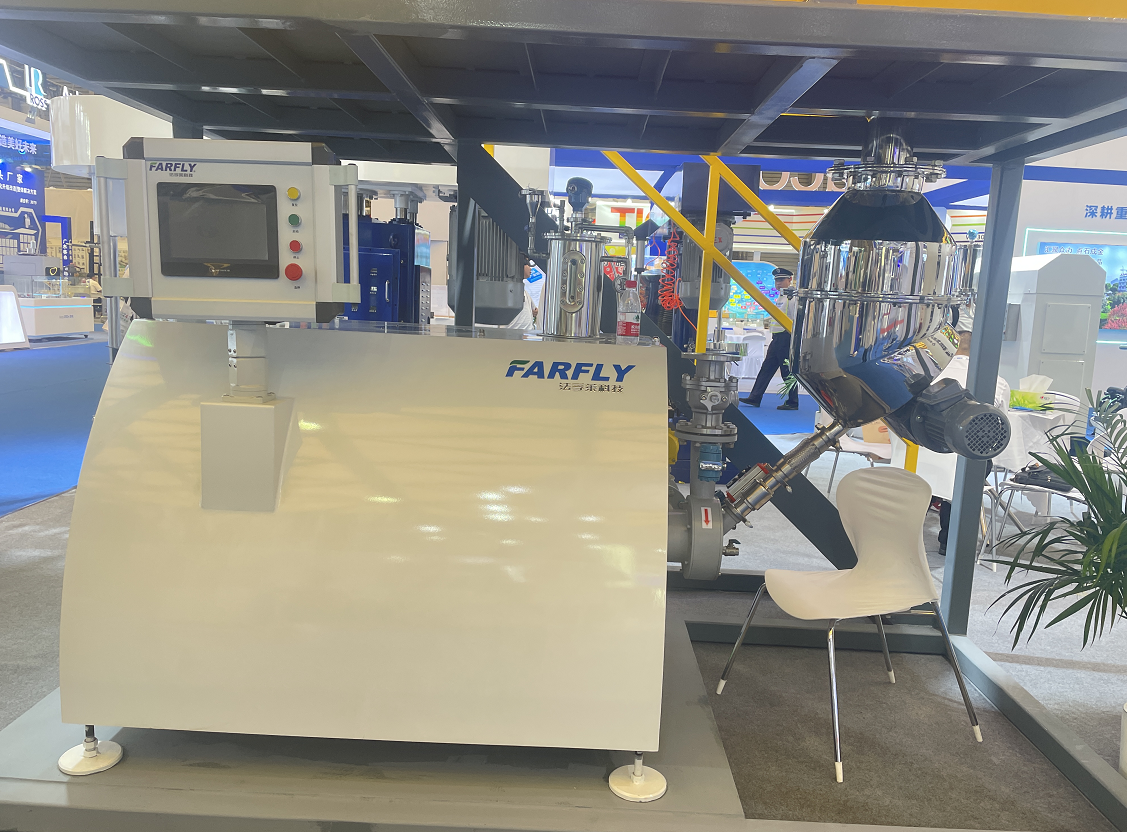

FIMS Super Oniline Powder Suction Machine

The powder absorption and dispersion process is completed in the grinding chamber (by the stator and rotor). The material is specially designed by the equipment through the impeller of the rotor in the rotation process at the end of the suction generated by the solvent, through the impeller rotation to throw out the solvent, due to the speed and linear speed is very high, the centrifugal force generated is relatively large. Negative pressure is generated at the center of the impeller through a higher flow rate. Then the powder inlet is opened, and the powder is sucked into the chamber through negative pressure. The stator and rotor in the chamber have a small gap. In the process of powder absorption, shear force is generated, so that the powder and liquid are mixed and emulsified.

The powder absorption and dispersion process is completed in the grinding chamber (by the stator and rotor). The material is specially designed by the equipment through the impeller of the rotor in the rotation process at the end of the suction generated by the solvent, through the impeller rotation to throw out the solvent, due to the speed and linear speed is very high, the centrifugal force generated is relatively large. Negative pressure is generated at the center of the impeller through a higher flow rate. Then the powder inlet is opened, and the powder is sucked into the chamber through negative pressure. The stator and rotor in the chamber have a small gap. In the process of powder absorption, shear force is generated, so that the powder and liquid are mixed and emulsified.